The workshop at Performance Conveyor Belting Ltd contains state of the art machinery, allowing us to produce a wide variety of conveyor belts.

Vulcanising presses

Equipped with vulcanising presses, the workshop utilises heat and pressure to create seamless joints and ensure the durability of chevron, sidewall, and other specialised belts. These presses are capable of handling high-tension environments, ensuring that the belts produced can withstand the rigors of heavy industrial use.

Injection moulding

In addition to vulcanising, the workshop features powerful injection moulding machines that form interlocking plastic pieces for modular belts. This capability is crucial for producing belts used in food processing, packaging, and automotive industries, where the flexibility and durability of modular belts are highly valued. Our skilled technicians can assemble the moulded modules into customisable belts, ensuring a perfect fit and optimal performance for diverse applications.

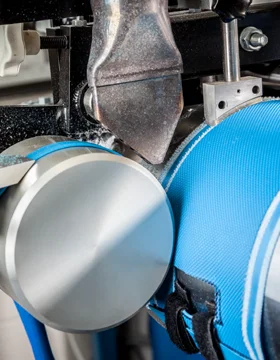

High-frequency welding

High-frequency welding machines are another key component of the workshop, used to attach flights and other components to the belts. These machines utilise high-frequency energy to create strong, reliable bonds that can handle the transport of small or bulk items up steep inclines. We have the ability to fabricate these belts up to 2.000m wide and offer same-day service for urgent orders.

Mesh belts

The workshop also excels in producing mesh belts, with weaving machines crafting belts with specific aperture sizes tailored for applications such as dewatering and drying. The mesh belts undergo heat treatment to enhance their durability and resistance.

Thermoforming

Thermoforming machines shape thermoplastic elastomer (TPE) belts, used in hygienic and precise applications like food processing and pharmaceuticals.

Our expert staff use their skills and our range of machinery to not only maximise efficiency, but to also respond swiftly to any diverse needs you may have.